In recent years, technology has changed the way we design, create, and manufacture products. One of the most exciting developments is the rise of laser engraving and laser cutting. Tools like the CO2 laser, laser cutter, and laser engraver have made it easier than ever to combine creativity with precision.

What was once limited to large factories is now available to small businesses, schools, makers, and even hobbyists at home. This article explores the progress of laser engraving technology, its practical uses, and why it continues to play such an important role in both industries and creative projects.

1. What Is Laser Engraving Technology?

Laser engraving is a process that uses a focused laser beam to mark or etch the surface of a material. Unlike traditional tools, lasers do not physically touch the material. Instead, the laser cutter or laser engraver directs a high-energy beam that changes the surface with heat.

There are different types of lasers, but the CO2 laser is one of the most widely used because it can cut and engrave a wide range of non-metal materials such as:

- Wood

- Acrylic

- Leather

- Paper

- Glass

This versatility makes CO2 laser machines a favorite for creative industries and manufacturing.

2. The Progress of Laser Engraving Technology

Laser engraving has seen major improvements over the past few decades. Some of the most important advancements include:

- Better precision: Modern machines can engrave details that are as small as a fraction of a millimeter.

- Faster processing: New laser cutters can complete tasks in minutes that once took hours.

- Improved software: Easy-to-use design programs allow beginners to create complex designs.

- More material options: From wood and acrylic to coated metals and glass, the list keeps growing.

- Energy efficiency: Today’s CO2 lasers are designed to use less power while delivering better results.

These improvements make laser engraving more practical, affordable, and accessible than ever.

3. CO2 Laser: The Core of Modern Laser Technology

The CO2 laser has become the most popular choice in both professional and creative fields. Its main advantages are:

- Works well with organic and non-metal materials.

- Creates clean cuts with smooth edges.

- Produces high-quality engravings with a clear finish.

- Affordable compared to other laser types, such as fiber lasers.

Because of these qualities, CO2 lasers are often used for:

- Custom signage

- Artistic engravings

- Prototypes and models

- Personalized gifts

- Packaging and branding

The CO2 laser is the foundation for most entry-level and mid-range laser cutters and laser engravers.

4. Laser Cutter vs. Laser Engraver: What’s the Difference?

Although people often use the terms interchangeably, there is a difference between a laser cutter and a laser engraver:

- A laser cutter is designed to cut through materials completely. For example, cutting shapes out of wood, acrylic, or fabric.

- A laser engraver is designed to mark or etch the surface of a material without cutting all the way through. This makes it perfect for adding logos, patterns, or text.

Many modern machines can do both tasks, which is why small businesses and makers often choose a combination machine.

5. Practical Applications of Laser Engraving Technology

The progress in laser engraving has opened the door to countless applications. Some of the most common include:

a) Creative and Artistic Use

Artists and designers use laser cutters and laser engravers to bring their ideas to life. From wall art and jewelry to 3D models, the precision of the laser makes it possible to create detailed designs with ease.

b) Small Businesses and Custom Products

Personalized products are in high demand. Businesses use laser engravers to customize gifts, trophies, phone cases, and home décor. This adds value and creates a personal connection with customers.

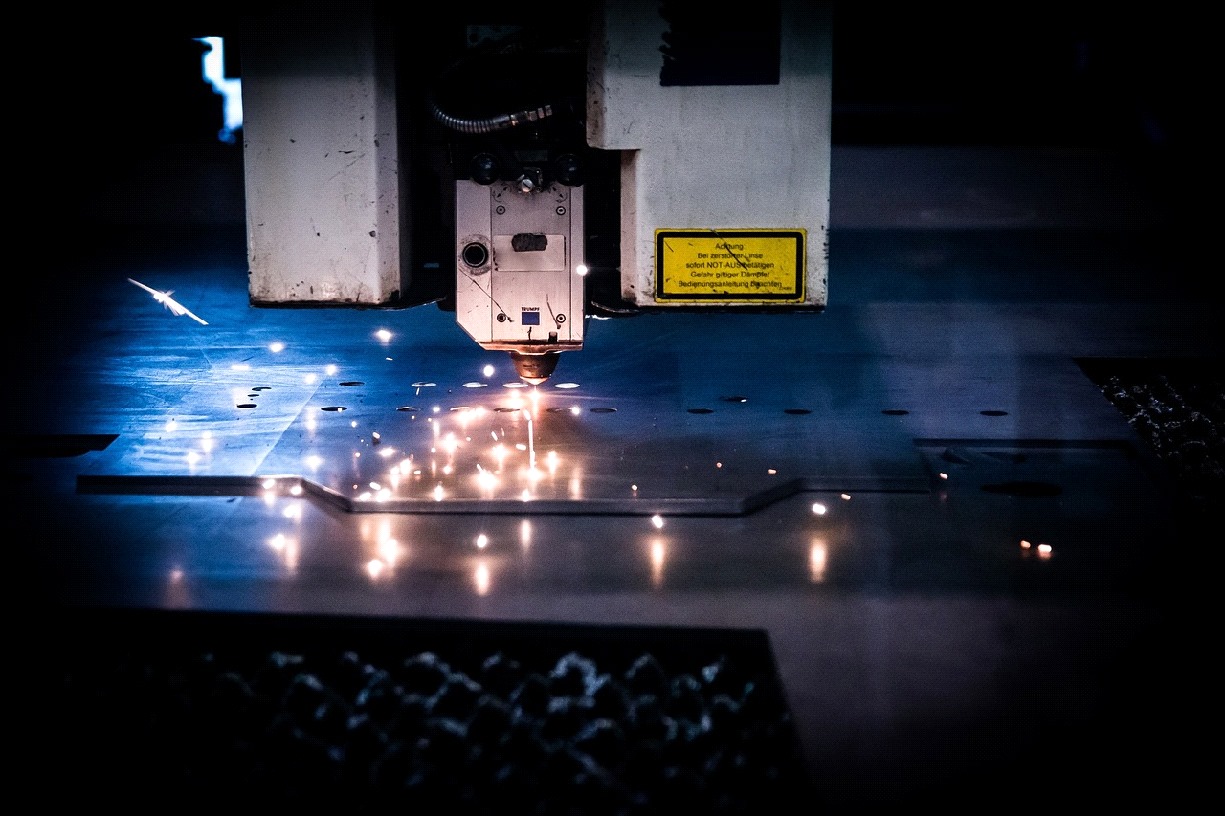

c) Industrial Manufacturing

In industries, lasers are used for serial number marking, product branding, and cutting parts with accuracy. The efficiency of the CO2 laser makes it suitable for mass production.

d) Education and Prototyping

Schools, universities, and start-ups use laser cutters for model making and prototypes. This helps students and inventors test ideas quickly and cost-effectively.

6. Benefits of Using Laser Technology

The evolution of laser engraving technology brings many benefits:

- Precision: Creates clean, sharp, and professional results.

- Flexibility: Works with many materials and design styles.

- Speed: Faster production times compared to manual methods.

- Customization: Every product can be unique and tailored to individual needs.

- Cost-effectiveness: Reduces waste by using exact cutting paths.

- Eco-friendly: Less material waste and more efficient energy use compared to older methods.

7. Accessibility of Laser Engraving Today

One of the most important changes is how accessible these tools have become. In the past, a laser cutter or laser engraver was only found in factories. Today, thanks to affordable desktop models, almost anyone can own one.

- Hobbyists can use compact machines at home.

- Small businesses can produce professional products without outsourcing.

- Online communities share free design files, tips, and tutorials.

This shift has made laser engraving not only a technology for professionals but also a creative hobby for individuals.

8. The Future of Laser Engraving Technology

The progress of laser engraving is far from over. Future trends include:

- Smarter software: With AI integration for faster design adjustments.

- Portable machines: Lightweight and wireless devices for mobile creators.

- Improved safety features: Making machines easier and safer to use at home.

- Greater material compatibility: Expanding the list of engravable and cuttable materials.

- Sustainability: Machines designed with eco-friendly systems to support greener production.

These advancements will continue to blur the line between professional manufacturing and creative hobbies.

The progress of laser engraving technology has changed how we design, create, and produce. With the rise of CO2 laser, laser cutter, and laser engraver, what was once an industrial process is now an everyday tool for creators and businesses alike.

Whether for art, business, education, or manufacturing, laser engraving combines speed, precision, and flexibility. It is not only shaping today’s creative world but also paving the way for a more innovative and sustainable future.