Your rebar tools set the baseline for build quality. After all, reinforcement steel can only do its job when processed to the angles and lengths required for the structure.

With the right rebar bender, rebar tier, and rebar cutter, you can keep early-stage work on schedule and help prevent off-angle bends and other mistakes that weaken a structure before the concrete even goes in. And of course, there’s a financial advantage. Clean cuts and consistent bends reduce waste and keep crews from spending additional time correcting preventable issues, helping your projects stay on schedule and within budget.

In this blog, we’re highlighting some of the best rebar tools available in Australia today so that you can choose the right setup for your reinforcement workload and make sure that your steel goes into the pour at the correct angles and lengths. We’re also covering the specs to look for based on the workloads and tolerances your site needs to meet.

What is the best rebar cutter?

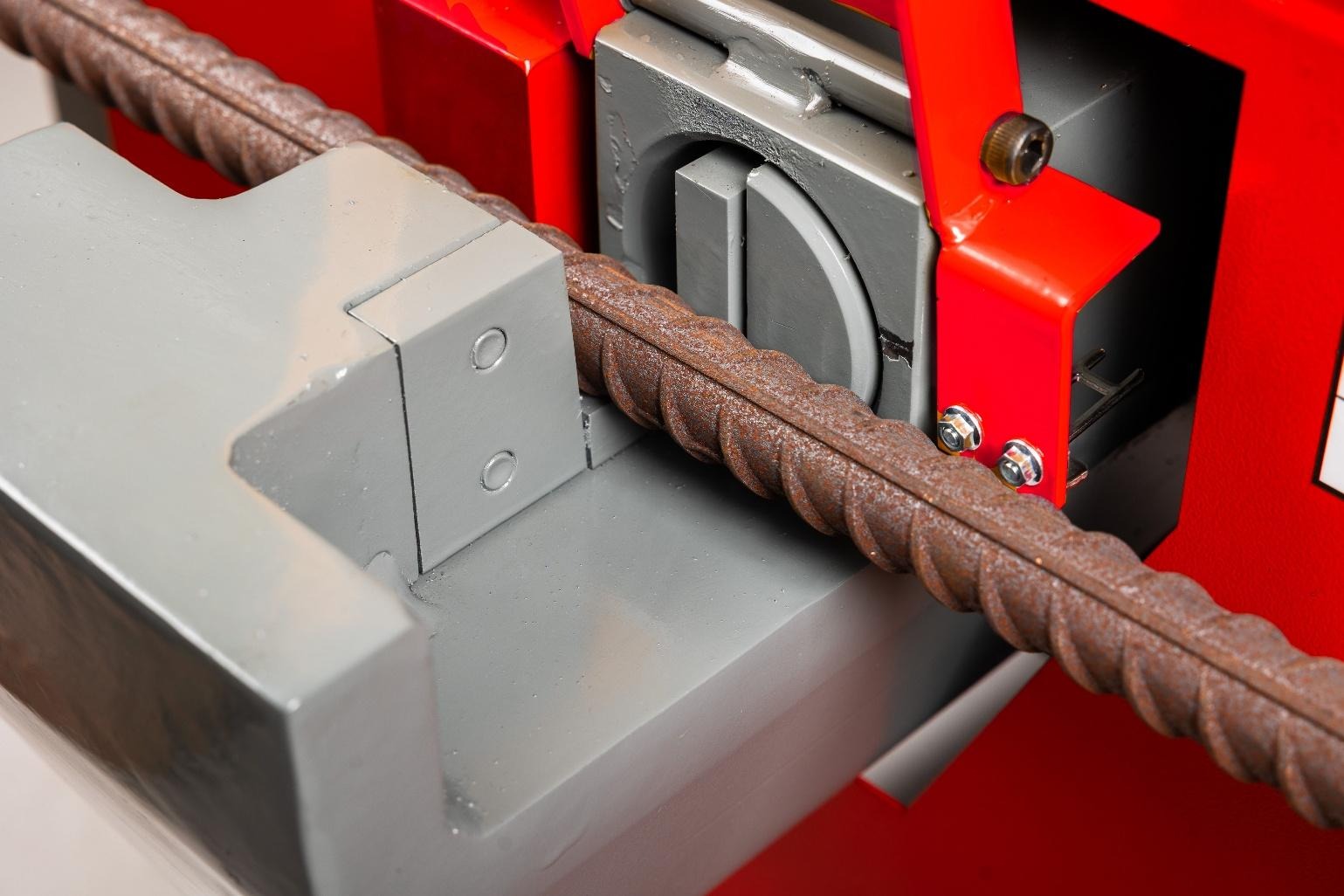

Rebar cutters have to slice reinforcement steel to exact lengths without distorting the bar, producing clean ends that maintain the bar’s structural integrity while preventing cracks or deformations that would interfere with load transfer.

RAPIDTOOL’s ERC-16 is among the best options for a reason. It works fast – roughly two seconds per cut – and its hydraulic system produces clean, controlled shearing that protects the steel from damage.

- Cuts up to 16 mm (D500N) through a solid, high-strength machine head

- 220–240V, 1200W motor running a tightly controlled hydraulic pump

- Shears the bar cleanly without producing sparks

- 8kg build that’s easy to move around the site

- Comes with a carry case, safety guard, and maintenance kit for regular servicing

Do you need a heavy-duty rebar cutter for large-scale or continuous cutting? The PRC-26X’s three-phase motor, multi-bar cutting capability, and industrial frame make it suitable for high-volume reinforcement prep.

- Cuts 6–26 mm bar with enough force to handle heavier reinforcement

- Capable of shearing several bars in a single cycle to speed up prep

- Three-phase motor built to run through long cutting sessions

- Fast cycle times under heavy load

- Hand or foot controls

- Full guarding

- Industrial frame with wheels for mobility

- Local parts and priority servicing available

What is the best rebar bender?

Rebar benders form steel accurately so each piece meets the precise angles required for foundations, columns, shear walls, beams, and precast elements. A quality bender helps prevent cracking, misalignment and inaccurate bends that can affect structural integrity.

RAPIDTOOL’s ERB-16 Electric 4‑16mm Rebar Bender is built for widespread structural tasks. You can rely on it to bend reinforcement consistently across a range of common angles.

- Bends a 90° angle in roughly five seconds

- Works with rebar up to 16 mm (D500N)

- Standard head covers 0–130°; Ø80 mm pin handles 0–90°

- Powered by a single-phase 220–240V, 1200W motor

- Guide bolt helps lock in repeatable bend angles

- Comes with an additional Ø80 mm bend pin

- Supplied with a carry case and maintenance kit

Meanwhile, RAPIDTOOL’s CRB-25 Industrial 6‑25mm Rebar Bender works well for medium-run processing and general structural reinforcement work. It’s compact enough for tight sites but strong enough for regular bending across a broad diameter range.

What is the best rebar tier?

Tying holds the reinforcement cage in place so that the steel doesn’t shift when the concrete is poured. But without rebar tying tools, workers end up twisting wire for hours, which strains their wrists and lower backs.

A rebar tier like RAPIDTOOL’s RT-40A locks the bars together in under a second and produces ties at the same height every time. Its tension control and dual brushless motor and feeding motor technology protect the tie quality and maintain repeatability across thousands of ties.

- 0.6-second tie speed with auto-reload and digital tension control

- 5,000+ ties per charge driven by dual brushless motors

- Slim arm for tight spacing; extension arm available for upright tying

- Tested past two million ties with a light, ergonomic build

- Up to eight times the output of manual tying; reduces labour and material costs

- Includes 2 x 18V batteries, charger, belt clip, carry case, and 4 x wire coils

- Works with high-grade RAPIDTOOL tie wire

Get the best rebar tools in Australia

Are you looking for equipment that can keep cuts clean, bends consistent, and ties uniform across long production runs? You can’t go wrong with RAPIDTOOL.

Every RAPIDTOOL rebar cutter, rebar bender, and rebar tier model is backed by local support and a national service agent network. Visit their website, rapidtool.com.au, or call 1800 955 755 to learn more about their products.